|

||||||

|

||||||

| |

||||||

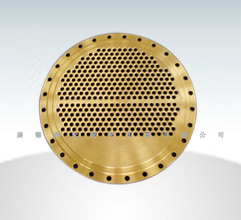

1. The forging material should be fabricated, inspected and accepted according to JB4726-2000,class Ⅲ. 2. The clad material should be fabricated, inspected and accepted according to NB/T47002.4-2009, class B1. 3. Ultrasonic testing according to NB/T47002.4-2009 before drilling holes. 4. The tube sheet grooves machined surface with the axis perpendicular to the vertical tolerance is 0.30mm,the surface has no defect which affects leak tightness. 5. The plumbness tolerance for tube hole center axis to tube sheet sealing face shall be not exceed 0.06mm. 6. The tube sheet after drilling holes to allow the bridge width 96% ≥ 4.48mm, 4% of the holes to allow the bridge width is 4.48mm. 7. The tolerance on bolt circle diameter and bolt hole spacing shall be ±0.6mm, the tolerance on random bolt hole spacing shall be ± 1.5mm. 8. The tolerance of the dimension for surface machined shall be in accordance with GB/T1804-2000 , grade m. |

||||||